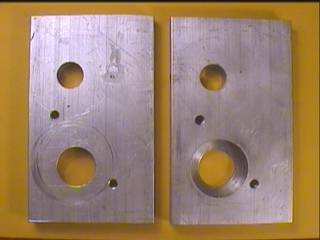

Side Plates - Part 1

For the side plates I used 1/2"x3"x5"

aluminum plate. I drilled two 5/8" holes.

One of the holes I would leave untouched for a bearing.

For the other hole I would machine out a recessed area for the eccentric to fit inside.

The larger part of the recessed area is 1 3/8".

The lower inner part of the area is 15/16" to

allow room for the bearing to protrude out the inner side of the plate.

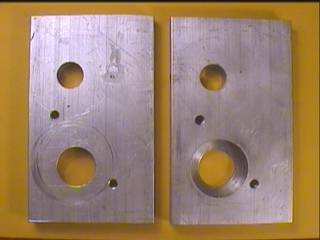

Here is a clear view of the plates without the eccentrics or bearings.

The hole in the plates on the lower right was going to be used to

secure the eccentric from moving once the gap was set between the rollers.

This was later changed to a set screw that can be seen on the next page

in the 3rd picture.

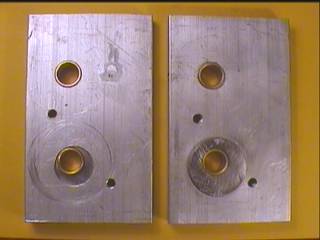

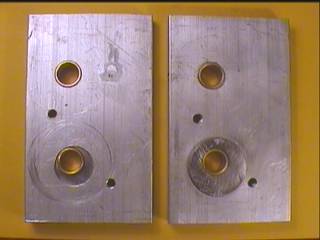

Here is a clear view of the plates with the

eccentrics and bearings. The hole in the plates on the left center

is used to secure the hopper and draft plate to the top

of the mill.

Previous Page Next page

|